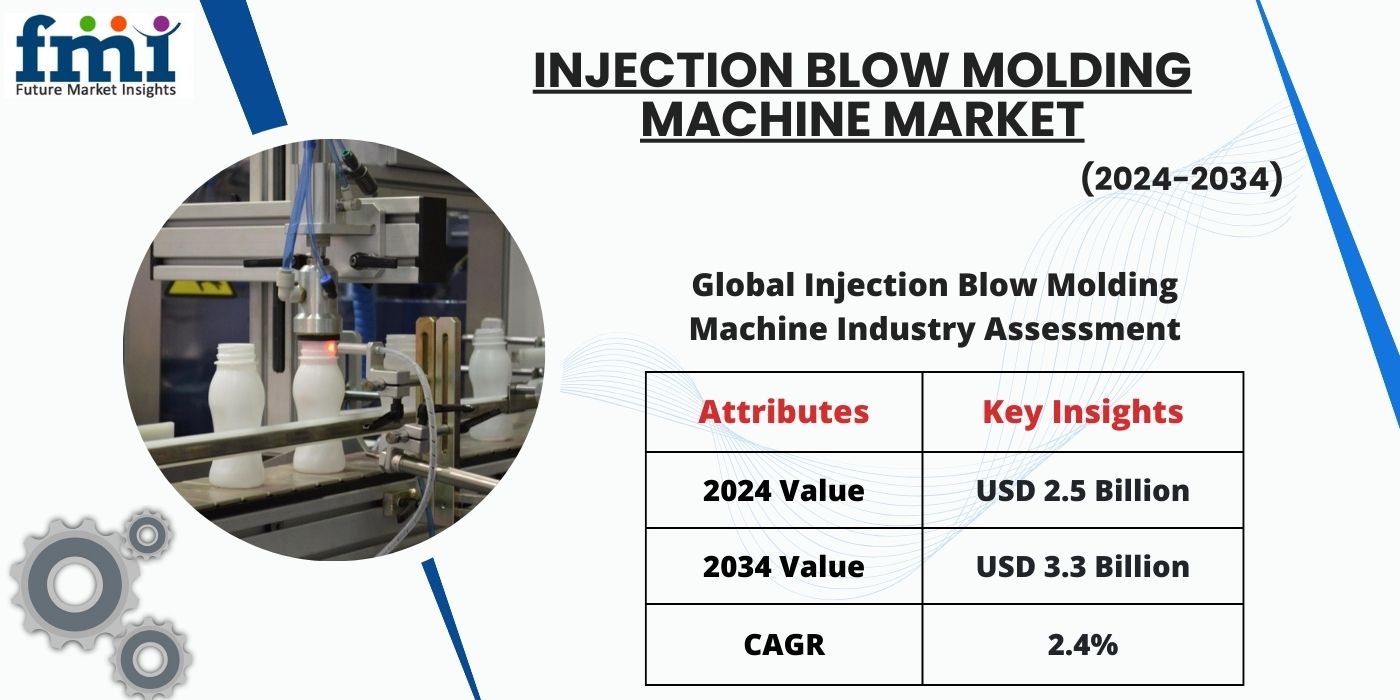

Global Injection Blow Molding Machine Market Poised for Significant Growth, Projected to Reach USD 3.3 Billion by 2034 | Future Market Insights, Inc.

NEWARK, Del, Aug. 28, 2024 (GLOBE NEWSWIRE) -- The global injection blow molding machine market has experienced substantial growth, reaching a size of USD 2.4 billion in 2023. Looking ahead to the forecast period from 2024 to 2034, the market is expected to exhibit a steady 2.4% CAGR, with the total market value projected to surge from USD 2.5 billion in 2024 to USD 3.3 billion by 2034. Blow molding is a manufacturing process that creates hollow plastic pieces. It's also used to make glass bottles. Injection blow molding, extrusion blow molding, and injection stretch blow molding are the three basic types of blow molding.

The healthcare and pharma industries are experiencing a surge in demand for high-quality, sterile packaging, leading to a surge in injection blow molding machines. These machines can produce precise medical containers and ensure product safety during cross-border shipping.

The pandemic has also accelerated this demand, with the aging population across the world. The consumer goods and beverages sectors are also driving this demand. These machines also help brands offer cost-effective solutions and versatility in container shapes.

Environmental concerns and the use of recyclable materials are also accelerating their adoption. Industrial breakthroughs, such as automation features and energy-efficient designs, are boosting the market.

Get the Complete Report! https://www.futuremarketinsights.com/reports/injection-blow-molding-machine-market

Growing industrialization in developing countries is expanding the market, with local manufacturers and multinational companies setting up production facilities in these countries. This growth in the packaging industry is attracting both local and multinational companies, further driving the demand for these machines.

However, high initial investment costs, skilled labour shortages, and environmental concerns hinder market growth. Companies also struggle to afford these machines due to high capital outlay, maintenance costs, and specialized knowledge.

What are the Major Factors Boosting the Injection Blow Molding Machine Market?

The packaging business has experienced recent expansion as a result of an increase in industries involved in packaged items, such as the food and beverage industry and the medicines industry. As a result, makers of tubes, bottles, and other packaging components are increasing their demand for injection blow molding equipment. As a result, the injection blow molding machine market is expanding.

the availability of numerous injection blow molding machines with varying capacities allows them to be used in the production of both tiny and large plastic products. Thus, injection blow molding machines are widely utilized for producing goods with capacities ranging from a few milliliters to thousands of liters.

The use of new technologies allows the injection blow molding process to be more energy-efficient and waste less raw materials. Furthermore, the use of cutting-edge computer-based technology and software enables efficient automation, lowering labor costs while increasing productivity. Thus, such factors are expected to drive the market during the forecast period.

What are the Factors Hindering the Injection Blow Molding Machine Market?

There are several constraints in the injection blow molding machine business, such as its reliance on petroleum, which, like the oil and gas sector, relies on millions of gallons of petroleum to make plastic products. Such a problem may restrict the global market for injection blow molding machine growth.

It also has a significant influence on the environment because this technology is heavily reliant on petroleum and is an essential component in the production of polymers. It necessitates numerous production methods, and more resources, and the process cannot be reduced, hence eliminating communication in the process.

Injection blow molding machines are confined to hollow parts, which means they can only be used for hollow parts and not solid parts. As a result, it becomes a significant disadvantage for the injection blow molding machine market. Moreover, when processing thermoplastics, the injection blow molding machine has issues with sheet thickness, which is difficult to control. Such obstacles will restrict the market growth in the future.

How is the Injection Blow Molding Machine Market Being Used for Packaging Application?

The packaging segment is predicted to develop at the quickest rate due to the increasing demand for packaging items in emerging regions due to high levels of consumerism. Polymers and their mixtures are used as plastic packaging materials. The efficiency and capacity of injection blow molding machines are extremely beneficial throughout the entire packaging process and help to reduce workload.

The expansion of the packaging industry will drive the demand for plastic compounds such as PE and PET in the future. This, in turn, will provide a significant opportunity for the injection blow molding market to grow throughout the forecast period.

Key Takeaways from the Market Study

- Rotary injection blow molding machine dominate the market with a share of 58.6% in 2024.

- Based on end-use, the food and beverage segment leads the injection blow molding machine market with a share of 41.8% in 2024.

- The injection blow molding machine market in India is anticipated to grow at a CAGR of 4.3% through 2034.

- The injection blow molding machine market in China is estimated to rise at a 3.9% CAGR through 2034.

- The injection blow molding machine market in France has the potential to increase at 1% CAGR through 2034.

- The United States injection blow molding machine market is predicted to rise by 1.5% CAGR through 2034.

- The injection blow molding machine market in the United Kingdom is very likely to grow at a CAGR of 1.1% through 2034.

“Companies in the injection blow molding machine market must be always on their toes to keep up with the latest updates in this industry. Medium and small-size enterprises can also collaborate with tier one companies to bring innovations in their product offerings”, Says Lead Consultant Ismail Sutaria in Packaging at Future Market Insights (FMI).

Competitive Landscape

The injection blow molding machine market is characterized by competition from companies focusing on technological innovation, precision, and energy efficiency.

Companies are also offering modular designs for easy upgrades and modifications. Some companies even compete on price, especially in emerging markets, while others focus on premium features and quality for high-end markets.

Compact machine designs attract customers with limited floor space. Notable companies in the market include SACMI IMOLA S.C., Jomar Corporation, Nissei ASB Machine Co., Ltd., and S.I.P.A. S.p.A.

Prominent Companies

- Parker Plastic Machinery Co., Ltd.

- Meccanoplastica Group

- Golfang Mfg. & Development Co., Ltd.

- Bekum Maschinenfabrik GmbH

- Jiangsu Victor Machinery Co. Ltd.

- Arburg GmbH + Co KG

Recent Developments

- R&B Plastics Machinery debuted its brand-new all-electric extrusion blow molding shuttle type at NPE in April 2024. With Yaskawa X absolute servo-motors and drives, the RBS-E550D provided a more compact design, more adaptability, and improved efficiency for demanding packaging applications.

- At NPE2024 in Orlando, Florida, in February 2024, Magic, a seasoned manufacturer of extrusion blow molding (EBM) machinery, unveiled its most recent all-electric Model ME T14-600-D EBM. The machine, with its double-station design, worked with a 2 x 230-mm head and a 15.4 ton clamping force with a 600-mm carriage stroke, providing greater production efficiency.

Key Segments of Market Report

By Orientation:

Injection blow molding machines are available in two variants when it comes to orientation: rotary and linear.

By End Use:

The market serves multiple end-use industries, including food and beverages, pharmaceuticals, personal care and cosmetics, home care, chemicals, etc.

By Technology:

In terms of technology, the market is classified into automatic and semi-automatic.

By Region:

The sector has been analyzed with the following regions covered: North America, Latin America, Europe, South Asia, East Asia, Oceania, and the Middle East and Africa.

Authored by:

Ismail Sutaria (Lead Consultant, Packaging and Materials) has over 8 years of experience in market research and consulting in the packaging & materials industry. Ismail’s strength lies in identifying key challenges faced by the client and offering logical and actionable insights to equip the clients with strategic decision-making power.

Ismail has been an instrumental part of several transformational consulting assignments. His key skills include competitive benchmarking, opportunity assessment, macroeconomic analysis, and business transformation advisory. Ismail is an MBA holder in Marketing and has a Bachelor’s Degree in Mathematics.

Have a Look at Related Research Reports on the Packaging Domain:

The pulp molding machine market is estimated to reach a valuation of USD 740.5 million in 2023. The market is expected to register a CAGR of 3.7% from 2023 to 2033.

The expansion of PET stretch blow molding machines is driven by rising demand for lightweight, durable packaging solutions, advancing technology, and increased efficiency in manufacturing processes across diverse industries.

The global blow fill seal technology market is estimated to be valued at USD 3,246.7 million in 2023 and is anticipated to reach USD 6,206.5 million by 2033.

The Europe injection molding machines market size is expected to surge at a CAGR of 4.3% from 2023 to 2033. The market is projected to expand from USD 3,475.3 million in 2023 to USD 5,288.9 million by 2033.

The demand for blown film extrusion machines is surging as industries seek advanced solutions for producing high-quality, versatile films used in packaging, agriculture, and various industrial applications.

The global pulp molding tooling market size is projected to be worth USD 923.5 Million in 2023. The market is likely to surpass USD 1,622.9 Million by 2033.

The demand for frozen food packaging machines is surging due to increasing consumer preferences for convenience and longer shelf life, driving innovations and growth in the packaging technology sector.

The growth of top-loading cartoning machines is driven by increasing demand for efficient packaging solutions, enhancing automation, and improving throughput in various industries, including food, beverage, and pharmaceuticals.

The global printing machinery market size is projected to reach USD 22,814.9 million in 2023. By 2033, the market is set to generate USD 38,572.8 million, meanwhile expanding at 4.7% CAGR.

The tissue paper converting machine market is valued at USD 1.30 billion in 2024 and is expected to reach USD 1.64 billion by 2034. The market is projected to exhibit a CAGR of 2.30% over the forecast period.

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

© Copyright Globe Newswire, Inc. All rights reserved. The information contained in this news report may not be published, broadcast or otherwise distributed without the prior written authority of Globe Newswire, Inc.